McCormick Industries, a leader in advanced manufacturing solutions, has released a new in-depth guide designed to help businesses and individuals better understand the intricacies of precision machining and its role in modern manufacturing. The guide, available on the company’s website, highlights the essential aspects of precision machining, detailing its processes, applications, and significance in critical industries like aerospace, medical devices, and electronics.

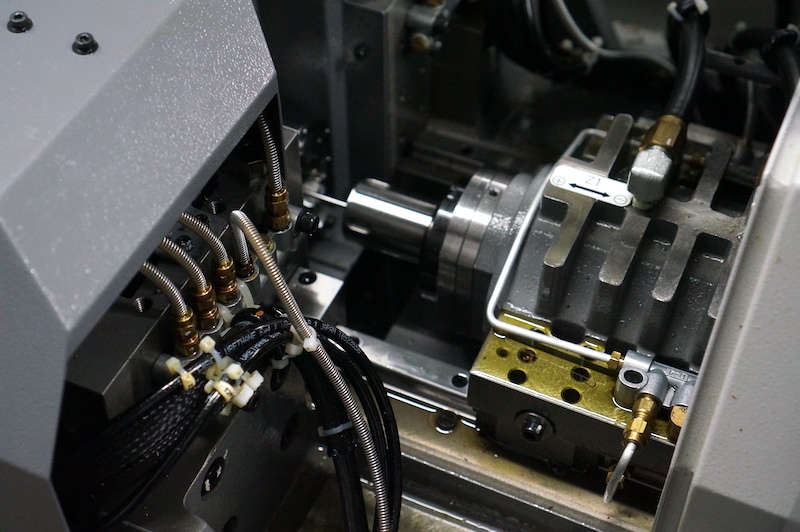

Precision machining is a subtractive manufacturing process that relies on cutting-edge equipment and expert design to create parts with highly intricate or complex geometries. The guide emphasizes how this meticulous approach has transformed industries by enabling the production of highly precise components that meet exacting specifications and demanding tolerances.

Gary Hermsen, CEO of McCormick Industries, commented on the importance of educating the market on precision machining. “Precision machining is at the heart of countless innovations and technologies we use daily,” he said. “We believe that by sharing our knowledge and expertise through this guide, we can help customers better understand how advanced machining can meet their specific manufacturing challenges.”

The guide walks readers through key aspects of precision machining, including the role of computer numerical control (CNC) machines. CNC machining forms the backbone of many precision manufacturing processes by using computer-aided design (CAD) and computer-aided manufacturing (CAM) software to automate production. This ensures not only high accuracy but also consistency, even across large production volumes.

McCormick Industries highlights the importance of multi-axis CNC machining, which enhances efficiency and precision by enabling machine tools to work along multiple axes simultaneously. Most standard CNC machines operate on three axes (X, Y, and Z), but precision machining often relies on 4 to 5-axis machines—or even machines with up to 9 axes for complex geometries and ultra-precise operations. According to the guide, this capability is critical for producing parts used in industries where precision and reliability are non-negotiable.

A significant portion of the guide is dedicated to Swiss precision machining, a specialized type of CNC machining that excels in creating parts with extremely tight tolerances. Swiss machining is particularly well-suited for manufacturing components for surgical tools, robotics, aerospace applications, and electronics. The guide notes that Swiss machining can achieve tolerances as precise as ±0.0001 inches, a level of accuracy necessary for many advanced technological applications.

Hermsen elaborated on the role of Swiss machining in McCormick Industries’ operations. “Swiss precision machining allows us to push the limits of what’s possible when manufacturing small, intricate components,” he said. “It’s a game-changer for industries that require absolute precision and consistency, and we’re proud to be at the forefront of this technology.”

Another focus of the guide is the versatility of precision machining in handling a wide range of materials, including aluminum, stainless steel, titanium, tool steel, and even exotic alloys. This flexibility enables manufacturers to produce parts tailored to the specific demands of various industries while maintaining tight tolerances and high repeatability.

McCormick Industries emphasizes that precision machining is particularly valuable when projects require exceptional consistency from one part to another. Whether manufacturing prototypes, small batches, or large production runs, the guide explains that precision machining ensures each component meets the same stringent standards, delivering reliability at scale.

The company’s guide also explores how precision machining contributes to faster production cycles by minimizing setup times and reducing human error through automation. By leveraging advanced technologies, precision machining allows businesses to achieve optimal results while maintaining efficiency, making it an attractive option for companies seeking both performance and cost-effectiveness.

The applications of precision machining extend beyond aerospace and medical devices to include industries such as automotive, power generation, and custom tooling. McCormick Industries’ guide underscores how the precision and durability of machined components can enhance product performance, ensuring reliability in even the most demanding environments.

Hermsen reflected on the future of precision machining, stating, “As industries evolve, the demand for precise, high-performance parts will continue to grow. Our investment in state-of-the-art equipment and our ongoing commitment to innovation ensure we’re prepared to meet that demand head-on.”

McCormick Industries encourages readers to explore their full guide on precision machining to gain a deeper understanding of the process and its benefits. The guide also outlines how businesses can collaborate with McCormick to develop tailored manufacturing solutions that align with their unique requirements.

###

For more information about McCormick Industries, contact the company here:

McCormick Industries

Gary Hermsen

920-954-9648

info@mccormickind.com

1103 South Perkins Street

Appleton, WI 54914