Leveraging METI’s “Fiscal 2025 Support Program for Energy and Manufacturing Process Conversion in Hard-to-Abate Industries”

Asahi Kasei, Mitsui Chemicals, and Mitsubishi Chemical have explored measures to promote decarbonization and optimize production capacity for their two ethylene manufacturing facilities in western Japan.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20260127526951/en/

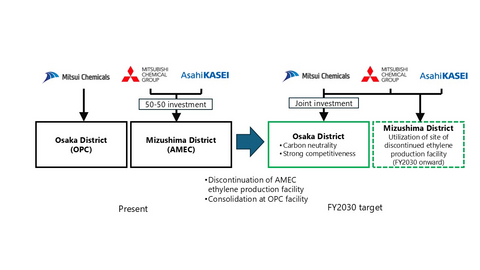

Conceptual diagram of future ethylene production framework

To achieve these goals, the three companies applied for and were selected for the “Fiscal 2025 Support Program for Energy and Manufacturing Process Conversion in Hard-to-Abate Industries” (HtA Support Program) by the Ministry of Economy, Trade and Industry (METI) to promote initiatives such as the use of biomass feedstock as an alternative to petroleum-derived resources.

The three companies have signed a basic agreement to establish a new joint operating entity for the two ethylene production facilities in western Japan, and to subsequently discontinue operations of the Asahi Kasei Mitsubishi Chemical Ethylene Corp. (AMEC) ethylene production facility of its Mizushima Plant in Kurashiki, Okayama Prefecture, and consolidate operations at the Osaka Petrochemical Industries, Ltd. (OPC) facility in Takaishi, Osaka, targeting fiscal 2030.

Utilizing the HtA Support Program, an initial facility to manufacture ethylene, propylene, and other decarbonized basic chemicals from bioethanol by applying the Revolefin™ technology, which is currently under development by Asahi Kasei, will be installed at the Mizushima Works of Asahi Kasei. Following verification of equipment performance, operation, and procedural aspects, the three companies aim to commence joint commercial production of the decarbonized basic chemicals in fiscal 2034. In addition, to address the discontinuation of the Mizushima Plant of AMEC which currently operates an ethylene production facility located within the premises of Mitsubishi Chemical, equipment modifications will be made by Asahi Kasei and Mitsubishi Chemical, and equipment modification will also be made at the Senboku Factory of OPC, which will serve as the site for consolidation. The ethylene production facility and related equipment of the Mizushima Plant of AMEC will be dismantled promptly after discontinuation of production. Following dismantling, the three companies will jointly examine opportunities to make use of the vacated site in ways that contribute to carbon neutrality.

Ethylene production is the upstream starting point of the petrochemical industry. Basic chemicals derived from ethylene are made into materials that are used in the manufacture of various products such as daily necessities, automobiles, and semiconductors. As individual companies face limits in reducing GHG emissions and making facilities carbon-neutral, there is a growing need for cooperation among multiple petrochemical manufacturers located nearby, through mutual provision of technology and joint implementation of measures that contribute to carbon neutrality.

Through the basic agreement, the three companies will deepen their alliance to drive the carbon neutrality and production optimization of ethylene facilities in western Japan with a spirit of transparent management with fair and rational sharing of costs and benefits of basic chemicals operations. Through the HtA Support Program, the three companies aim to accelerate the transition to competitive decarbonized basic chemicals, expand carbon-neutral markets in each company’s business fields, and build sustainable business models.

Outline of the HtA Support Program

Project name |

Promotion of decarbonization and optimization of ethylene production facilities in western Japan |

Implementation framework |

Asahi Kasei, Mitsui Chemicals, and Mitsubishi Chemical |

Locations |

|

Scale of investment |

¥21.2 billion (including a maximum subsidy application amount of ¥10.4 billion) |

Content of investment |

Structural transition: Ethylene production facilities and related equipment (related to receiving, shipment, utilities, etc.) Process transition: Initial production facility for Revolefin™ |

Expected CO2 emissions reduction |

Structural transition (Scopes 1 and 2): 506,000 t-CO2/year reduction (compared to FY2023 [Osaka] and FY2024 [Mizushima]) |

Scheduled completion |

By the end of fiscal 2029 |

Integration of ethylene production facilities

Timing of production optimization |

Fiscal 2030 target |

Method of production optimization |

Discontinuation of AMEC ethylene production facility and consolidation at OPC facility |

Equity ratio |

Based on the proportion of offtake volumes among the three companies |

Integration structure |

Implemented through a joint operating entity (JV) |

Timing of joint operating entity establishment |

TBD |

Ethylene production capacity (with maintenance turnaround) |

Before consolidation: 951,000 tons/year

|

View source version on businesswire.com: https://www.businesswire.com/news/home/20260127526951/en/

Contacts

North America Contact:

Asahi Kasei America Inc.

Christian OKeefe

christian.okeefe@ak-america.com

Europe Contact:

Asahi Kasei Europe GmbH

Sebastian Schmidt

sebastian.schmidt@asahi-kasei.eu